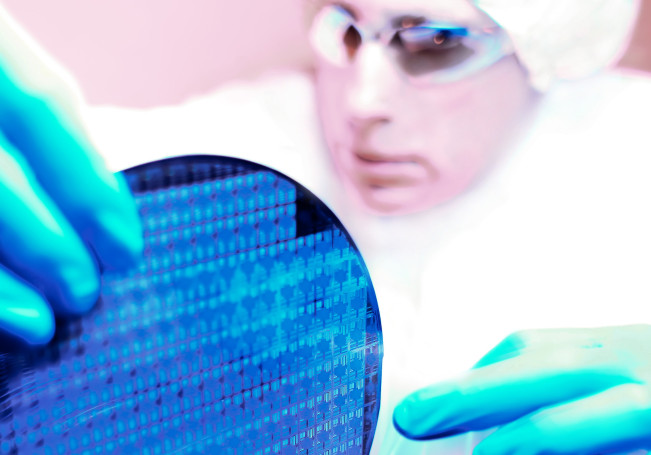

Mixed Acid Etchants (MAE’s) are one of the many high purity blends that Columbus Chemical Industries (CCI) excels at manufacturing for supply to the semiconductor market. MAE’s are proprietary ratios of electronic grade nitric acid, hydrofluoric acid, acetic acid and water. Addition of surfactants with MAE’s can also increase the efficiency of wetting the substrate surface. Mixed Acid Etchants are typically used in chemically etching silicon but can be used for other applications.

Mixed Acid Etch Production

Mixed acid etch blends are manufactured under highly controlled and monitored conditions at CCI. Our controlled manufacturing environments and packaging cells allow us to maintain the quality of the high purity acid and surfactant components throughout the process, ensuring consistency and solid performance across all lots of the same formula.

CCI produces high purity deionized water (DI Water) in both our Phoenix, AZ and Columbus, WI facilities for use in our mixed acid etchant blending. Both facilities regularly test to >17.5 megohm in conductivity, contributing to maintaining the purity of the raw materials used through to packaging of the mixed acid etchant.

Each lot of raw material used, and each batch of etchant produced is tested per its set specification. SPC tracking options are also available for highly sensitive applications.

As specifications require, CCI also provides product filtering with particle count testing to ensure particles are below required thresholds.

Benefits of Premixed MAE

There are many benefits in having your Mixed Acid Etch contract manufactured:

- Consistency across all lots of material

- Higher yield reproducibility

- Batch testing cost reduction

- Impurity levels guaranteed below set specifications

- Convenience of having a ready to use product

- Minimize handling of highly hazardous concentrated acids

- Minimize storing hazardous raw materials onsite

- Elimination of need for mixing vessels/equipment

- Limiting shipments of hazmat materials from multiple vendors

CCI also provides warehousing and inventory management options for etchants. This allows the economic benefits of large scale batch sizing, while providing the convenience of delivery volumes based on your storage and usage requirements, ready to ship when needed from WI or AZ.

Contact CCI to discuss your etchant needs today