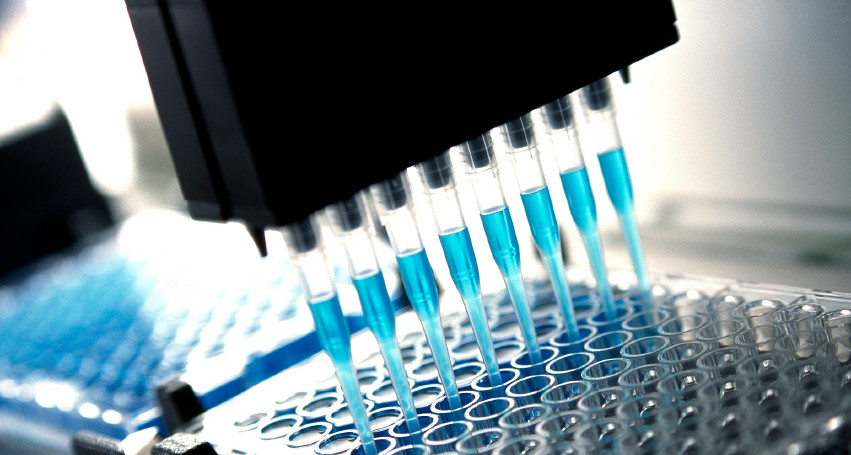

Columbus Chemical Industries has a long history of supplying high purity raw materials into the pharmaceutical industry with the specific niche of supplying to Active Pharmaceutical Ingredient (API) manufacturing facilities. Supplying chemistry into this market requires a detailed understanding of the pharmaceutical industry, and the Quality Systems required to support supplying into the API raw material market.

Robust Quality System to support API Market

Our Quality Assurance team works diligently to ensure that all quality expectations are met. Columbus Chemical Industries has passed countless audits from regulatory agencies such as the FDA, as well as global and national pharmaceutical organizations. We are ISO 9001:2015 certified, maintain compliance with the most current requirement cycles of Responsible Distribution administered by the Alliance for Chemical Distribution (ACD, formerly NACD), and are cGMP compliant.

Our commitment to meeting and exceeding the most up to date requirements set by industry regulators and leaders ensures that the raw materials required for your API’s are being handled appropriately and in the proper environments to meet the requirements of the pharmaceutical industry.

Custom Packaging for API Raw Material Market

To meet each customer’s unique requirements, CCI offers cGMP facility chemical packaging with custom package options for both liquid and solid materials. Our custom packaging options for API raw materials help our pharmaceutical partners:

- reduce risk

- Smaller and lighter containers reduce chance of injury and strain due to heavy lifting

- Batch sized containers reduce the traffic of putting material away after use, limiting chances for accident and unnecessary exposures

- maintain quality

- Smaller or batch sized packages limit overexposure of material to environment conditions they might otherwise experience over time during frequent opening/closing of larger packages

- Eliminate packaging components, such as fiber bags or drums, that may carry moisture or easily cause contamination compared to poly or glass containers

- increase efficiency

- Batch sized packages can be pre-measured to fit an applications exact needs, reducing employee time spent measuring

- Batch sized packages reduce time spent on put-away of materials after use

Our cGMP complaint production and packaging area allows us to also provide dilutions and custom chemical solutions to the pharmaceutical industry for a variety of applications.

Our procurement team includes sourcing specialists that have scoured the globe to locate those hard to find materials. If you aren’t currently second sourced on all of your mission critical chemical components, contact Columbus Chemical today to speak to one of our chemical specialists.